With globalization, companies are adopting many suppliers, manufacturers, and logistics from far and wide. A good supply chain model minimizes waste, enhances productivity, and would go on to further build a competitive advantage for a company.

Among some of the biggest names like Amazon, Apple, and Walmart, significant effort has been put into streamlining supply chain strategies for efficiency and profitability. Indeed, these companies partner with suppliers, invest in highly advanced logistics, and build streamlined distribution networks to join their customers with consistently high expectations of their products and services.

This article provides some of the real-world cases in supply chain management: 7 of them are strategies that can be successfully utilized by businesses to maximize their processes. These examples present best practices in inventory control, supplier collaborations, and logistics management, helping companies regardless of their size.

Key Components of Supply Chain Management in Leading Companies

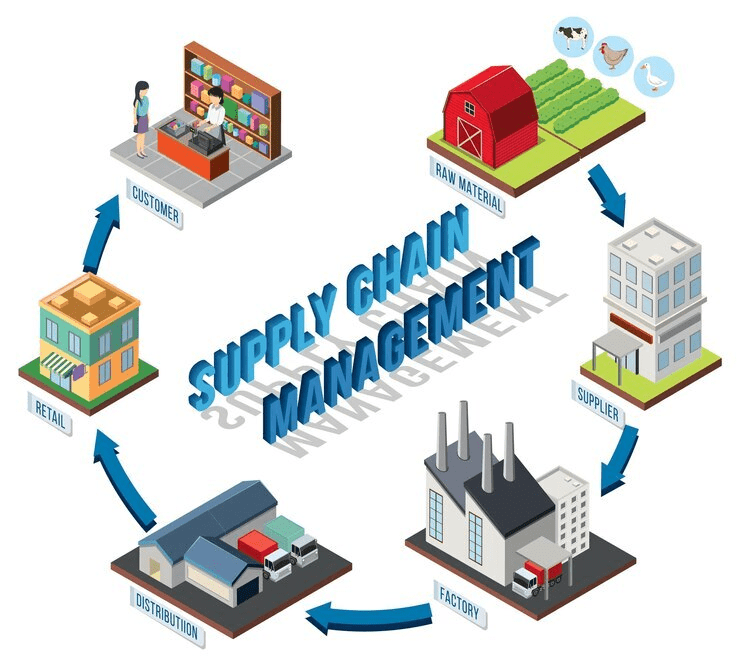

An effective supply chain consists of several interconnected processes, each playing a crucial role in ensuring operational efficiency. The primary components include:

- Sourcing and Procurement – Selecting reliable suppliers to ensure the steady availability of raw materials.

- Manufacturing and Production – Transforming raw materials into finished products through efficient processes.

- Warehousing and Distribution – Storing and managing the inventory to meet market demands while ensuring there is no overstock.

- Transportation and Logistics refer to the effective movement of goods from manufacturing plants to retailers or directly to consumers.

- Supply Chain Optimization refers to the application of data-oriented techniques that enhance operating efficiency whilst minimizing costs.

The companies that keep on improving these parameters are getting better customer satisfaction, lower costs, and improved competition in the market. The following examples showcase how top businesses excel in supply chain management through innovation and strategic planning.

1. Supply chain excellence, Amazon represents the benchmark.

The e-commerce behemoth has constructed one of the most advanced supply chain models to deliver millions of orders within 24 hours. The foundation of Amazon’s success is proper logistics timing.

Amazon Supply Chains

Situation of Fulfillment Centers

Amazon maintains global fulfillment operations with over 200 fulfillment houses strategically located near all major urban centers. Warehouses stock fast-moving consumer goods to minimize shipping time and logistics costs.

Automated Warehouse Operations

Amazon automated and robotized warehouse operations to increase the speed of sorting, package making, and inventory tracking. It eliminates human error and expedites the processing of orders.

Last-Mile Delivery Optimization

Amazon uses its fleet alongside third-party delivery services to optimize last-mile distribution. This technique assures timely delivery in urban areas of all orders, whether large or small.

Predictive Inventory Management

Utilizing advanced analytics, Amazon can predict customer buying patterns. This way, it efficiently stocks high-demand items, which helps to reduce bottlenecks in the supply chain.

Key Takeaways

According to the very different Amazon’s ability to blend automation, strategic warehousing, and data-driven decision-making has set the benchmark in supply chain management. It is this emphasis on innovation and efficiency that other companies can emulate in their logistics operations to enhance their performance.

2. Apple – Master of Supplier Network

Apple’s supply chain model is one of the best organized and efficient ones in the technology sector. It sources materials from bureaucratic suppliers around the world while ensuring optimum quality control and costs.

Global Suppliers Cooperation

Apple works with suppliers in over 43 countries for the components of the highest quality for competitive prices. This diversification of supply sources allows Apple to have fewer risks associated with regional disruption.

Just-in-Time Inventory

Apple’s just-in-time inventory system ensures that components are sent in just the right quantities as and when needed during the assembly process. This minimizes the cost of excess inventory while keeping production cycles running efficiently.

Quality Control

Apple maintains a very high standard of quality control, conducting audits of its suppliers regularly to maintain its well-deserved reputation for quality.

Logistics and Distribution

Shipping is done both by air and by sea to balance the cost of transportation with the speed of it. Distribution is ensured through a network of global retail outlets and direct-to-consumer online sales.

Key Takeaway

Apple’s leadership in supply chain management results from its clever balancing of cost management with quality assurance. Companies can learn from supplier diversification, efficient inventory management, and stringent quality standards in Apple.

3. Tesla’s Vertical Integration Strategy

Unlike most traditional automotive firms that rely heavily on third-party supply chains to be effective, Tesla has taken a slightly different approach: it has a vertically integrated supply chain model. This would mean that whatever it can do regarding raw materials and critical components must be manufactured within the company.

Gigafactories as Production Plants

There are many gigafactories owned and run by Tesla that produce its batteries, motors, and other important components. This is achieved by internally manufacturing these parts to eliminate the terms of dependence on external suppliers while also providing greater control over production costs.

Primary Source of Raw Materials

Lincoln, cobalt, and nickel are three elements that make up almost every electric vehicle battery, and Tesla owns them. This helps the company curb shortages in raw materials and price fluctuations.

Key takeaway

The vertical integration model of Tesla gives it an edge against competitors by reducing supply chain vulnerabilities and providing tighter control of product quality and innovation. Similar types of supply chain strategies could be acquired by businesses to garner more ownership of operations and reduce dependence on third parties.

Toyota’s Lean Manufacturing Supply Chain

Toyota is renowned for its lean supply chain management methodologies whereby waste and inefficiency are eliminated and improvement is continuous.

Just-in-Time (JIT) Manufacturing

By this delivery system, the JIT system-on which Toyota pioneered ensures that parts come precisely when they are needed, thus minimizing the costs generated from storage and increase in efficiency.

Collaboration with Suppliers

Toyota and all the suppliers that it works with form a highly trusted network of suppliers, thus nurturing a relationship between them that stretches beyond just quality to efficiency as well.

Key Takeaway

Toyota’s lean practice minimizes waste and thereby maximizes efficiency, and it is a good example of what ought to be done when optimizing supply chains.

5. Unilever’s Sustainable Supply Chain

Unilever has developed poor carbon footprints and distinguished sustainable green supply chains along all supply chain systems.

Sustainable Sourcing

Obtaining raw materials from responsibly sourced origins and ensuring sociability in palm oil, tea, and other commodities. Energy Efficient Distribution

The company places money into low-carbon ways of logistics, thereby reducing emissions in transport and warehouses.

Key Takeaway

Unilever proves that businesses can combine sustainability and supply chain efficiency to create a positive global impact.

6. Nike’s Agile and Responsive Supply Chain

Nike has built an agile supply chain that enables it to respond quickly to changing market demands and trends.

Nearshoring and Regional Production

Nike locates production closer to key markets, reducing lead times and improving flexibility.

Digital Supply Chain Innovation

Nike uses real-time data analytics to manage inventory and demand fluctuations effectively.

Key Takeaway

Nike’s supply chain agility allows it to stay ahead in a fast-changing industry.

7. Coca-Cola’s Global Supply Chain Efficiency

Coca-Cola operates one of the most extensive supply chain networks in the world, with a presence in over 200 countries. The company’s ability to manufacture, distribute, and market its beverages globally is a testament to its supply chain excellence.

Franchise Bottling System

Coca-Cola follows a franchise bottling model, where it produces concentrate and sells it to independent bottling partners. These partners manufacture, package, and distribute the final products. This decentralized approach enables Coca-Cola to scale operations efficiently while maintaining local market adaptability.

Localized Production

Instead of exporting beverages from a few centralized locations, Coca-Cola sets up regional production plants. This reduces shipping costs, shortens lead times, and allows the company to comply with local regulations.

Sustainable Logistics

Coca-Cola has invested heavily in eco-friendly transportation and packaging solutions. By optimizing routes, using energy-efficient vehicles, and incorporating recyclable materials, the company reduces its environmental impact while maintaining efficient distribution.

Key Takeaway

Coca-Cola’s localized production, franchise bottling model, and sustainability efforts make it a leading example of supply chain management. Businesses can learn from Coca-Cola’s ability to balance global reach with regional efficiency.

Zara’s Lightning-Fast Fashion Supply Chain

Zara is a fashion powerhouse, thanks to its highly responsive supply chain model.

Vertical Integration

Unlike most fashion brands, Zara controls most of its production, reducing reliance on third-party manufacturers.

Rapid Design-to-Shelf Cycle

Zara gets new designs from the sketchpad to store shelves in as little as two weeks, keeping up with fast-changing fashion trends.

Key Takeaway

Zara’s ability to react quickly to trends and control production makes it a dominant force in fast fashion.

Conclusion

A well-planned supply chain management strategy is crucial for businesses striving to improve efficiency, cut costs, and meet customer expectations. Companies like Amazon, Apple, Tesla, Toyota, Unilever, and Nike demonstrate how businesses can refine their supply chain models to remain competitive in fast-evolving markets.

Looking for a reliable sourcing partner?

If you’re looking to simplify your supply chain and find trustworthy suppliers, Brand New MD is here to help. We specialize in sourcing solutions that are perfectly suited to your business’s unique needs. Our team works closely with you, understanding your goals and finding reliable suppliers that can deliver quality products on time and at the right price. Let us take the guesswork out of sourcing, so you can focus on growing your business with confidence.