Do you want to reduce procurement costs while maintaining high-quality standards? Are you looking for ways to optimize your procurement process? Procurement cost analysis is one key tool in achieving this goal. This powerful strategy allows organizations to evaluate their procurement processes, identify inefficiencies, and implement effective solutions to minimize expenses.

This blog will explore procurement cost analysis, its significance, and strategies for effective cost optimization.

What is Procurement Cost Analysis?

The complete expenses connected to obtaining goods or services form the basis of procurement cost analysis. The entire procurement cycle demands assessment including material sourcing at the beginning through delivery at the end and all follow-up processes thereafter.

This assessment lets organizations check for price selectivity while showing potential cost-saving opportunities for the costuming processes. Organizations using modern procurement technologies as indicated by a 2023 Deloitte survey experienced a reduction in their procurement expenses by 49%.

Key Areas of Procurement Cost Analysis

Sourcing Cost Analysis

The analysis focuses on the costs connected to supplier identification and selection and their business engagement. The expenses required to complete market research along with supply chain management and price negotiation belong in this category. Businesses that conduct effective sourcing cost analysis select quality suppliers able to provide affordable high-quality products.

According to Gartner’s research 60% of organizations that achieve top performance perform sourcing cost analysis routinely for maintaining their competitive edge.

Cost Analysis in Procurement

A complete assessment of all procurement-related expenses makes up this process. The analysis involves direct spending (product prices) together with indirect costs (transportation and warehousing) and hidden spending (executive department expenses). Through thorough cost analysis during procurement organizations obtain a complete cost picture which allows them to discover financial savings possibilities.

According to current business research companies can achieve annual savings reaching up to 20% through systematic identification and removal of costly yet invisible procurement expenses.

Total Cost of Ownership (TCO)

TCO is generally a strategic criterion utilized in procurement cost analysis studies. It means the total cost of owning, operating, and maintaining a product or service from purchase through disposal. Realizing TCO is important to organizations because it aids in decision-making about investment by extending the analysis beyond the initial cost. Studies by McKinsey & Company show that firms that fine-tune their TCO model can attain cost reductions of between 10 and 15 percent during the product life cycle.

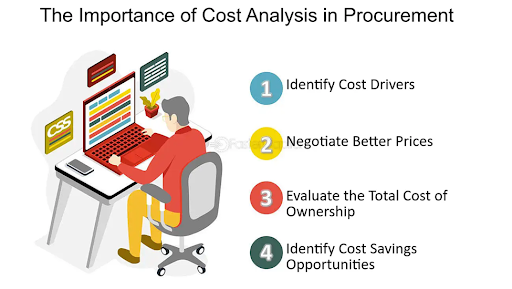

Why is Procurement Cost Analysis Important?

Procurement cost analysis is essential for several reasons:

Identifying Cost Inefficiencies

By critically scrutinizing the aspects within a firm, one can locate loopholes where they spend much or aspects where many cost factors could be minimized.

Improving Supplier Relationships

When costs are broken down and analyzed, organizations are better placed to engage suppliers or negotiate better prices to create incremental advantages from the partnerships.

Optimizing Operational Efficiency

The analysis of procurement costs identifies operational costs that are too high in a business to be used much while still agreeing on the areas that have the most unoptimized and high procurement costs to be used less in the future.

Enhancing Strategic Decision-Making

Cost control is a core aspect of cost analysis that contains significant information needed in the decision-making process to enable the procurement function to match with overall organizational strategies.

According to a Gartner study, businesses that focus on cost optimization strategies across the procurement process can achieve savings of up to 15% annually

Strategies for Cost Optimization in Procurement

Optimizing procurement costs requires a multi-faceted approach. Here are some strategies that can help organizations achieve significant cost savings:

Leverage Technology and Automation

There are many ways that procurement technology and automation tools can be applied to various procurement processes to decrease the amount of human mistakes and paperwork. For instance, integrating purchase orders, invoices, and supplier communications through procurement software saves most of the time when dealing with numerous generated overheads. However, using technology means the availability of accuracy and real-time capability that improves decision-making and cost facts of procurement.

As stated by McKinsey, procurement automation systems help optimize procurement costs by 10-20%. For more on how digital product strategy enhances operational efficiency, check out this guide on digital product strategy.

Conduct Competitive Sourcing

Competitive sourcing is a procurement technique in which bids are sought from several suppliers for precisely the same product or service. This system forces the supplier to offer their best prices, which allows for great discounts.

Besides, competitive sourcing will enable businesses to gain a more extensive market vision, including potential suppliers that provide better terms or higher-quality products. Refer to this strategic product features blog for more information on sourcing strategies.

Implement Just-in-Time (JIT) Inventory

Just-in-time inventory is a system of purchasing and receiving inventory, with the primary goal of minimizing costs by fetching inventory only as required in the production line. This strategy has further changed the requirement for a vast warehousing area and has decreased the warehousing and holding costs. It also helps businesses avoid investing in unsold stock as it leads to better cash flow and eliminates problems of stock hold that can be obsolete. JIT inventory can reduce holding costs by 25%, according to a recent Harvard Business Review article.

Negotiate Better Supplier Contracts

Supplier negotiations are a critical component of procurement cost analysis. Establishing long-term, mutually beneficial relationships with suppliers can lead to more favorable pricing, discounts, and payment terms. Organizations should also explore options such as bulk buying, consolidated shipments, and flexible payment schedules to reduce costs further.

Focus on Total Cost of Ownership (TCO)

Therefore, instead of businesses adopting the purchasing price of products, there is a need to adopt the TCO strategy in procurement. This strategy covers every incidental cost right from the time of shipping and installation, maintenance during its use, and finally disposal. If businesses take the time to look at the total cost of a product down the line instead of just the first cost—which may be slightly higher—they are making wiser decisions that result in future savings.

Optimize Supplier Performance and Collaboration

Building strong relationships with suppliers is essential for achieving cost optimization. Collaboration with suppliers can improve product quality, delivery times, and reduced costs. Regular performance evaluations and open communication with suppliers ensure that both parties align their goals, resulting in lower procurement costs.

Consolidate Procurement Activities

Promoting procurement integration on a department or business unit basis can result in scale economies as firms can negotiate better prices and/or minimize transaction costs. For instance, instead of individual managers running around looking for paper, ink, and toners for their departments, a dedicated procurement team can undertake this function, thus improving the efficiency of the procurement process through the ability to consolidate volumes that lower the price per unit of supply.

Conclusion:

In today’s competitive marketplace, understanding procurement cost analysis and implementing cost optimization strategies can give your business a significant edge. Whether leveraging technology, negotiating better supplier contracts, or focusing on the total cost of ownership, every step towards optimizing procurement processes can lead to tangible cost savings.

For more insights on how entrepreneurs can spot opportunities for new products, explore this blog on product opportunities.