Imagine two businesses selling the same product. One runs like a well-oiled machine, with smooth logistics, lower costs, and satisfied customers. The other struggles with stock shortages, delivery delays, and inefficiencies, barely staying afloat. What sets them apart? The right supply chain model.

Did you know? Companies that optimize their supply chain can reduce costs by 15% and speed up order fulfillment by 50% (McKinsey). A well-structured supply chain model is not just a business strategy—it’s a game changer.

There is no magic formula that works for every company. The ideal supply chain model depends on factors like industry type, market shifts, and operational goals. Whether your focus is on cost-cutting, adaptability, or sustainability, picking the right supply chain model can make all the difference.

Let’s dive into the 10 most effective supply chain model, their benefits, and the industries they best serve.

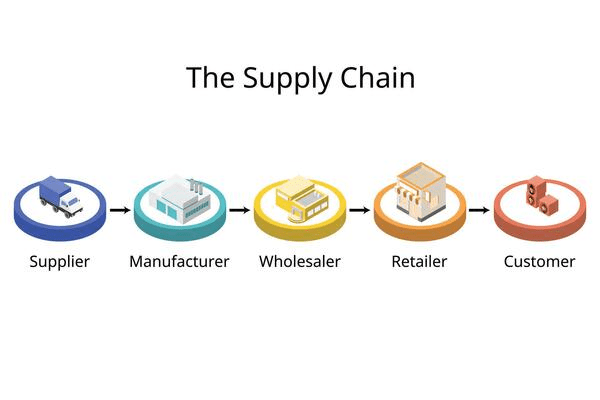

What Is a Supply Chain Model?

A supply chain model is the strategic plan that determines how products move from suppliers to customers. It covers sourcing raw materials, production, distribution, and final delivery. A well-planned supply chain boosts efficiency, minimizes waste, and keeps customers happy.

The supply chain industry is evolving rapidly. Experts predict that by 2027, the global supply chain market will reach $37.41 billion. Companies worldwide are investing in supply chain planning models to enhance resilience, manage disruptions, and improve overall performance.

Types of Supply Chain Management Models: A Quick Overview

Before exploring each model, let’s break them down into broad categories:

- Lean vs. Agile: Lean focuses on cutting excess costs and waste, while agile adapts swiftly to changing demands.

- Traditional vs. Digital: Traditional models rely on manual operations, while digital supply chain models integrate automation and data-driven solutions.

- Predictable vs. Resilient: Some businesses work with stable, long-term supply chain planning models, while others prepare for sudden market shifts and disruptions.

Choosing the right supply chain model is essential for optimizing operations and staying competitive.

Now, let’s explore the top 15 supply chain models and their best applications.

Top 10 Types of Supply Chain Models

Continuous Flow Model – Best for Steady Demand

Businesses with predictable, high-volume demand, like automobile and food production, rely on the continuous flow model. This method ensures a steady supply of materials and finished products, reducing downtime and excess inventory.

Pro Tip: Companies using this supply chain model cut waste by 40% compared to traditional approaches (Harvard Business Review).

Fast Chain Model – Ideal for Fast-Moving Markets

Industries such as fashion and consumer electronics require speed and flexibility. The fast chain model helps companies release new products quickly and stay ahead of trends.

Did you know? Brands like Zara use this model to restock stores within 48 hours, maintaining an edge over competitors.

Efficient Chain Model – Designed for Cost Savings

This model is perfect for cost-sensitive industries, such as fast-moving consumer goods (FMCG). It reduces production and distribution costs through bulk purchasing and streamlined logistics.

Pro Tip: Companies using the efficient chain model focus on process optimization, supplier negotiations, and economies of scale to remain competitive.

Agile Supply Chain Model – Built for Uncertainty

For industries like pharmaceuticals and technology, demand can change overnight. An agile supply chain model helps businesses pivot quickly.

Did you know? 74% of companies say agility is essential to prevent supply chain disruptions (Deloitte).

Custom-Configured Model – A Tailored Approach

Companies that need customized production and logistics benefit from this hybrid supply chain model. It combines elements from other models to create an optimized approach tailored to specific needs.

Flexible Supply Chain Model – Managing Seasonal Demand

For businesses with fluctuating demand, such as holiday retailers, the flexible supply chain model enables companies to scale up or down as needed.

Pro Tip: This model helps businesses reduce seasonal inventory waste by up to 30% through just-in-time (JIT) inventory management.

Green Supply Chain Model – Sustainability-Focused

With more consumers seeking eco-friendly brands, businesses are shifting to green supply chain models, reducing carbon footprints, and adopting sustainable materials.

Did you know? 73% of global consumers prefer brands that prioritize sustainability (Nielsen).

Lean Supply Chain Model – Eliminating Excess

Inspired by Toyota’s Just-in-Time (JIT) system, this model aims to reduce inventory excess, minimize waste, and maximize efficiency.

Industries like automotive and electronics manufacturing benefit from the lean supply chain model, ensuring smooth operations with minimal resources.

Resilient Supply Chain Model – Preparing for Disruptions

The COVID-19 pandemic emphasized the need for resilient supply chains. Companies using this model focus on risk management and contingency planning to prevent disruptions.

Did you know? 93% of businesses are now rethinking their supply chain strategies to enhance resilience (Forbes).

Demand-Driven Supply Chain Model – Powered by Real-Time Data

This model leverages data analytics to predict and meet demand accurately, reducing inventory costs while ensuring product availability.

Pro Tip: 90% of supply chain leaders are investing in data analytics to improve forecasting and avoid stock shortages (Gartner).

Conclusion

A well-structured supply chain model is essential for improving efficiency, reducing costs, and gaining a competitive advantage. By selecting the right supply chain model, businesses can optimize their operations, enhance resilience, and drive long-term success.

Looking for an expert sourcing partner to strengthen your supply chain? Contact Brand New MD for tailored and reliable sourcing solutions.