How To Manufacture A Toy (Toy Manufacturing Process Start To Finish)

Our Experience Spans Over 40 Years and 1000s Of Toys! (...and still going strong)

We tend to see toys as fun, irreverent products that we give to our children to keep them occupied and having fun. You may even remember your favorite childhood memories were playing with your toy collection and taking care of your most fond items seemed to be the most important thing in the world.

For that reason, then, toys are more than irreverent products we bring into our homes and throw out a year later, as they can provide years of happiness to our children, and may even help them learn as they develop.

Yet what may seem like a fun product or a simple merchandised item on the surface is a product that has had a lot of thought put into the design process to make it work and ensure its suitability for a wide array of consumers. Furthermore, toys are subject to strict regulatory standards to make sure that they are heavily unlikely to contribute to harm or injury.

Say you wish to bring a toy to market. It’s important to be fully aware and informed about the large undertaking this is, and what stages of this process you will invest in along the way. From conception through to manufacturing and marketing, our A-Z guide will help you achieve that goal.

The Design Stage

A Foremost Idea

The design stage kicks off with the introduction of an idea. This is usually best achieved with a form of innovation that gives you legal room to define a new idea as your own. This idea must be unique and marketable. Remember how expansive the toy market is, and just how much competition is out there. For instance, the Toy Fair in New York has up to and over 7,000 toy ideas contributed to it each year.

A design may be predicated on the idea of helping children learn, of making a previously understood and accepted toy design more modular, or even improving the biodegradability of a certain toy line using special and innovative materials. An idea is great, but it’s untethered unless matched appropriately with:

Market Research

Costing

Costing your product is essential. How much will the raw materials be to develop this product? In general, the manufacturing process will help cut down on these costs thanks to bulk orders of supplies.

What price do you hope to enter the market at? An estimated recommended retail price is best informed by gathering information about how much parents are willing to spend within a certain market. If the toy needs to be replaced or needs additional replacement parts to keep operational, the upfront cost may not be justified in being so high, whereas one-time-purchase goods that are built to last may warrant a higher entry price.

Costs can also be established by the competition in the market. Games consoles, for instance, can ask for higher prices thanks to how little competition there is and how much market share is divided between a range of companies.

Final Designs

The final design process can begin after curating all of the prior necessities. Establishing the materials you will use to design your product, the safety features you will implement, making sure compliance is met, and branding your product appropriately are all essential steps to consider here.

Final designs will also include decisions relating to the product’s name, the colors it may come in, and of course, UX design.

UX design is a discipline dedicated to making products of any kind more accessible and easy to understand by the target audience. With toys, this means identifying every single manner by which someone could interact with the product, defining the likelihood by which someone will come across that function, and how it helps your product or how that eventuality must be mitigated. UX design is a complex process that some firms choose to outsource.

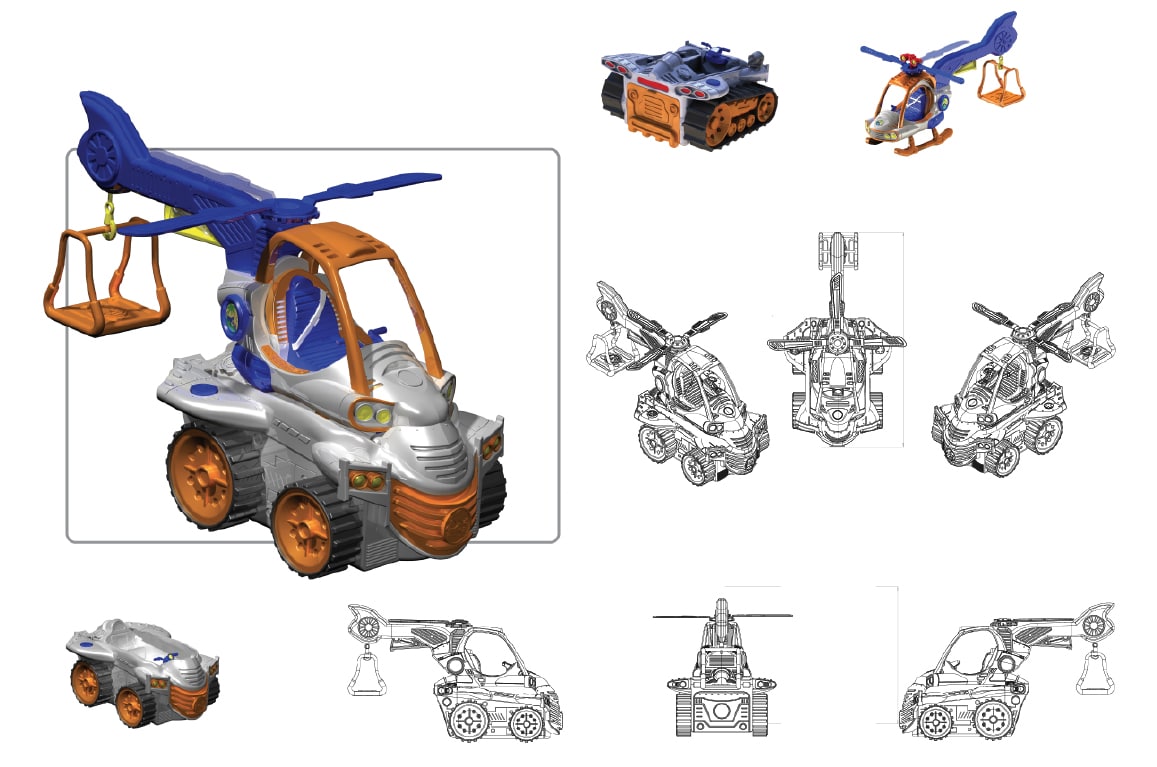

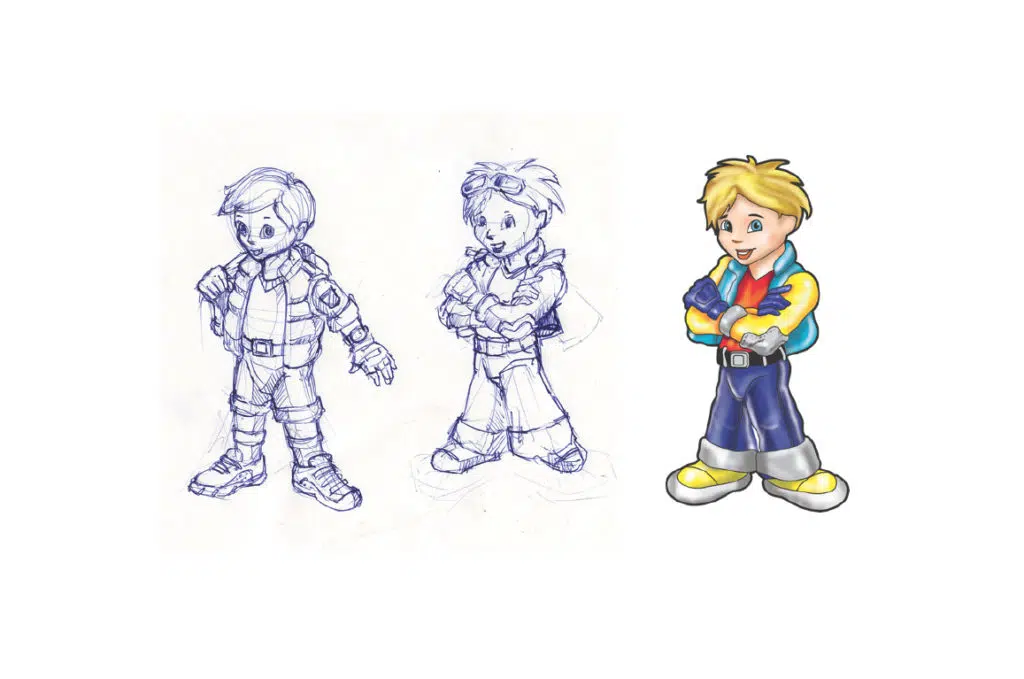

The final design will include detailed planning stages. Then, you will move on to preparing sketches of the toy and 3d renders to ensure it is feasible for manufacturing and that the design is actualized in 3d space. From there, outsourcing a manufacturing firm to provide you with a prototype can serve as a proof-of-concept that helps you move with confidence to your manufacturing process.

Legal Protections

Safety & Regulations

Toys are subject to intensive safety regulations that must be adhered to in every part of the manufacturing process. For instance, a limit on small parts in toys designed for infants could be in effect depending on the country you’re manufacturing and selling in. Non-toxic manufacturing processes may also be essential.

Furthermore, the materials you may be able to form a certain product out of, such as certain plastics, may define your costing strategy and how reliably long-lasting a product may be. It’s important to pore over the compliance requirements your product, and by extension, your firm will be subject to.

The Manufacturing Stage

Sourcing A Manufacturer

Once you are happy with your design, research, cost, and legally protected intellectual property, it’s important to work out the many stages involved in manufacturing.

Finding an appropriate factory, and the manufacturing firm that runs it and is happy to take on your product can take some time. Hiring a sourcing agent is a common means of helping you identify your options, but you can approach manufacturing firms yourself should you wish to.

What matters is that you source a transparent firm that is both able to procure the materials you need for development, while also providing the specialized skills and experience necessary to cultivate your product. A standard toy manufacturer may or may not have the proper utilities necessary to cultivate your approach. It’s important to verify that they do at every level.

Essential vetting you must take part in will involve making sure the factory has the molding parts necessary to craft your product, or if those must be ordered in. Inspecting the quality of their assembly lines, the condition of their factory, and of course, the storage of manufactured goods can help solidify reliability.

We’d also recommend taking a keen interest in quality assurance and compliance testing. This will make sure that your toy is not only as robust as necessary for your brand, but that it goes above and beyond compliance to make sure that regulatory limits are never a problem. Toys, more often than not, come in packaging, and so it’s best to identify this firm can also manufacture that or if they will need to transport your goods to another firm as part of your supply chain.

Note that sometimes, concessions in how much of this process is undertaken by a select manufacturing firm must be made, depending on the production necessities of your toy. It might be that dividing the manufacturing and packaging development between two firms is necessary, as the former may only be used for specialized design manufacture you struggle to find elsewhere.

Domestic v. Overseas

Depending on your needs and the specialist manufacturing necessities you require, deciding between domestic and overseas manufacturers should be aided by a handy ‘pros and cons’ list. In general, domestic manufacture is seen as more favorable by consumers living there, as it’s been proven that US customers, for instance, will be happy to pay over 20% of the cost of an item if it means the product is manufactured within American borders.

Overseas manufacturing, such as using a manufacturing firm in China (the biggest manufacturing powerhouses on the planet), can come with many benefits too, such as giving you access to much cheaper production thanks to reduced labor costs. Of course, it’s worth considering the cultural and language barriers that may come into play no matter where you opt to situate your production overseas.

The Supply Chain

The supply chain of your manufacturing process involves the planning, procurement, manufacturing, delivery, retailing, and consumption of your process.

The manufacturing element of this concerns itself with demand forecasting (that is, deciding how much volume should be manufactured and adjusting to market trends as necessary), identifying bottlenecks in your process, accounting analysis, and optimizing your productivity via shrewd management.

Manufacturing firms worth their salt should be able to prove to you why they’re an asset to your supply chain and how comfortably they can integrate within that. This also means that you need to confidently assess every step of that journey to know what you require from a firm like this. This can help you more readily make your decision.

The Marketing Stage

Branding Your Product

Branding your firm is a crucial element of establishing yourself as an operational entity, and most of that work should have been done before going through with manufacturing. Yet it’s also true that products reflect on a brand as much as a brand reflects on its products, and so making sure the two are combined and synchronized is important.

A good way to start with this is to think about copywriting, used as a tool to introduce your conceptual design and unique presence to an audience. Using imperative phrases, words that will appeal to your target audience, and writing an ideal marketing brief to help you get your point across is essential.

To use an example from earlier, sporting equipment for young boys will need to be seen as action-focused, teamwork-aiding, and a product that can aid their performance, making them feel super cool and composed no matter what sport they play. Graphic design, such as that used on your packaging, can also increase the effect of how you introduce yourself into this market. All of these practices must be invested in and researched for maximum effect.

Appealing To Buyers

Ultimately, you need to know who is most likely to purchase your product and how to appeal to them. Even if your toy is designed for young children, you won’t secure a single sale from them directly. It’s their parents or caregivers that will be making those purchasing decisions.

All marketing material, then, must be mindful of this fact. For instance, many toy manufacturers do their best to market their item as the hot-button toy to purchase before the Christmas season, at a time where spending is heightened and parents are more likely to do their research into toys and their uses.

Qualities that score big with parents are toys that are proven to be educational in some sense (though not necessarily academic), long-lasting, safe, fun, and creativity-inducing. If you can hit these major markers, you’re in with a better chance of success.

With this advice, we hope you can manufacture a toy with confidence and care, paying attention to the A-Z essentials of the process.

Toy